Views: 0 Author: Site Editor Publish Time: 2023-11-10 Origin: Site

Introduction to Bamboo

Bamboo is a versatile and sustainable material that has gained popularity in various industries, including construction and interior design. Bamboo is a gift from Mother Nature, it grows naturally on bamboo mountains. it doesn’t require fertilizer or pesticide, not to mention intensive caring and maintenance. the bamboo stems underneath will sprout new shoots every year, and it takes only 4-6 years for a bamboo to its full maturity for industrial use. Bamboo is not rare, but widely spread in China. Then why bamboo panels are still so expensive?

Introduction to Bamboo Panel

One of the most sought-after bamboo products is bamboo panel, which is widely used for interior furnishing, such as furniture, kitchen cabinets, countertops, stair treads. Also used for structural beams, ceiling and wall cladding etc. However, many people wonder why bamboo panel is relatively more expensive compared to other materials. In this article, we will explore the reasons behind the higher price tag of bamboo panels.

Harvesting Bamboo is a Job Young People Unwilling to Do

harvesting bamboo requires skilled laborers who carefully select mature bamboo stalks, ensuring their quality and sustainability. And it takes many years of experiences to get the knowledge. Nowadays young people prefer to work in a factory of office, skilled bamboo farmers become rare, and in short supply. In most cases, bamboo grows on steep mountains, with long distance to the roads. it is a tough job harvesting bamboo and dragging them to loading spot.

Complicated Production Process

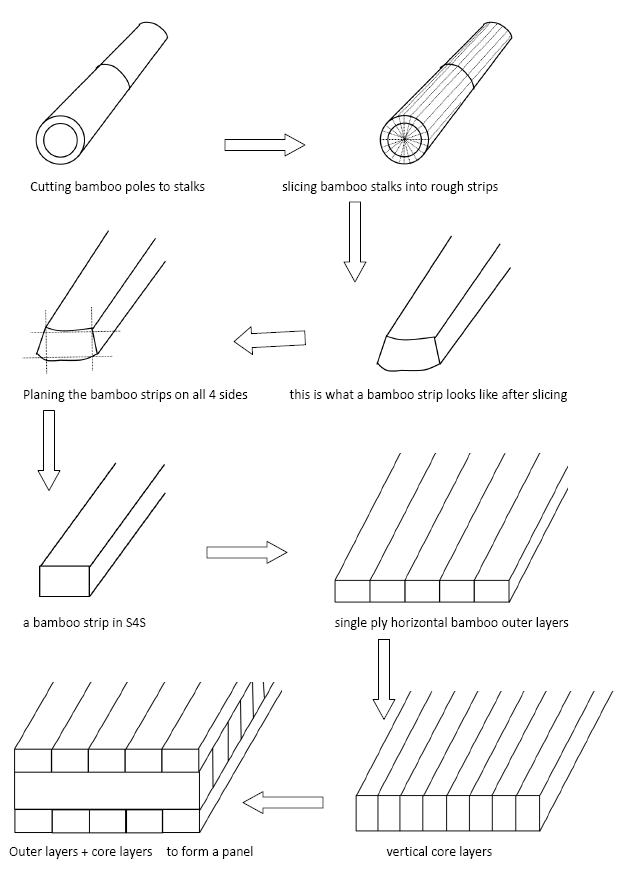

It is not an easy job turning bamboo poles into high end furniture grade bamboo panels. The production process goes like this,

Harvesting bamboo, cut into stalks, splitting stalks into strips, rough planing of strips, carbonizing for carbonized color or boiled in hot water with H2O2 for natural color, drying process, fine planing to make the strips S4S, sorting bamboo strips for color matching and defects, gluing, pressing single ply horizontal sheets, pressing single ply 19mm thick vertical sheets, slicing 19mm thick vertical into 2mm, 3mm, 5mm, or 8mm thickness as face veneer, preparing core layers, laminating outer layers and core layers to form a multiply bamboo panel, trim the 4 edges, sanding, repairing, QC, packaging.

Harvesting bamboo, cut into stalks, splitting stalks into strips, rough planing of strips, carbonizing for carbonized color or boiled in hot water with H2O2 for natural color, drying process, fine planing to make the strips S4S, sorting bamboo strips for color matching and defects, gluing, pressing single ply horizontal sheets, pressing single ply 19mm thick vertical sheets, slicing 19mm thick vertical into 2mm, 3mm, 5mm, or 8mm thickness as face veneer, preparing core layers, laminating outer layers and core layers to form a multiply bamboo panel, trim the 4 edges, sanding, repairing, QC, packaging.

a simplified version of the production process as below,

Labor- Intensive Production Process

One of the primary factors contributing to the higher cost of bamboo panels is the labor-intensive production process involved. the production process of bamboo panel is not highly automated, lots of work has to be done by hand.

Heavy Investment

It is not cheap to start a bamboo panel factory, big investment is necessary. We need a big plant area, a boiler, lots of press machines, kiln drying facilities, various types of wood cutting machines, sanding machines.CNC routers etc.

Environmental Protection

The Chinese government is paying great attention to environmental protection, bamboo factories are required to adopt new technologies to minimize contamination.

Quality and Durability

Bamboo panels are highly regarded for their strength, durability, and aesthetic appeal. The quality of bamboo panels largely depends on the manufacturing process and the selection of premium bamboo stalks. To ensure consistent quality, manufacturers often invest in advanced machinery and technologies, which adds to the production cost. Additionally, the durability of bamboo panels makes them a long-term investment, as they can withstand wear and tear better than many other materials.

Market Demand and Limited Supply

The increasing popularity of bamboo panels has led to a surge in market demand. However, the supply of high-quality bamboo is limited, especially when considering the sustainable sourcing requirements. The limited supply and high demand create a competitive market, driving up the prices of bamboo panels.

Transportation and Logistics

Transportation and Logistics

Bamboo is mainly grown in regions like Southeast Asia, where it thrives in tropical climates. The transportation and logistics involved in shipping bamboo panels from these regions to other parts of the world can significantly impact their cost. Import taxes, shipping fees, and handling charges all contribute to the overall price of bamboo panels.

Conclusion:

Bamboo panels offer a sustainable and visually appealing alternative to traditional wood materials. While their higher price tag may initially seem daunting, understanding the labor-intensive production process, long maturation period, sustainable sourcing requirements, quality and durability, market demand, and transportation logistics helps explain why bamboo panels are relatively more expensive. Investing in bamboo panels not only supports environmentally friendly practices but also ensures a long-lasting and aesthetically pleasing addition to any project.