loading

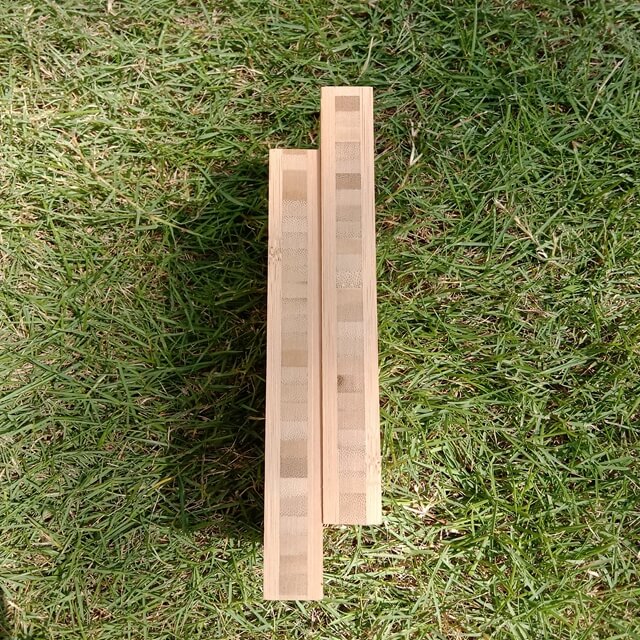

Cross-ply bamboo plywood is an engineered bamboo product where layers of bamboo strips (veneers) are stacked with their grain directions perpendicular to each other (typically at 90° angles) and bonded under high pressure. This cross-lamination mimics traditional plywood construction, providing balanced strength and stability in multiple directions.

Cross-Laminated Structure

Alternating layers (usually 3, 5, or more) are arranged with grains perpendicular to each other.

Reduces expansion/contraction and warping, improving dimensional stability.

Balanced Strength

Unlike longitudinal plywood (which is strongest along the grain), cross-ply has uniform strength in both length and width.

High Durability & Moisture Resistance

Often treated with adhesives (such as phenolic resin) for water resistance, making it suitable for humid environments.

Eco-Friendly & Sustainable

Made from fast-growing bamboo, a renewable alternative to hardwood plywood.

Smooth Surface & Aesthetic Appeal

Can be sanded to a fine finish, suitable for visible surfaces in furniture and interiors.

✔ Furniture (tabletops, cabinets, shelves) – Stable and warp-resistant.

✔ Flooring & Wall Paneling – Handles heavy loads without bending.

✔ Countertops & Worktops – Resists moisture and wear.

✔ Doors & Partitions – Less prone to warping than solid wood.

✔ Structural Panels (in some cases) – Used where multi-directional strength is needed.

| Feature | Cross-Ply Bamboo Plywood | Longitudinal Bamboo Plywood |

|---|---|---|

| Grain Direction | Layers perpendicular (90°) | All layers parallel |

| Strength | Balanced in all directions | Stronger along the grain |

| Stability | More dimensionally stable | Can warp if unsupported |

| Best For | Furniture, countertops, general plywood uses | Beams, flooring, long spans |

| Moisture Resistance | Often higher (due to resins) | Depends on adhesive used |

✅ Multi-directional strength – No weak direction.

✅ Less prone to warping – Ideal for large panels.

✅ Smooth finish – Better for visible surfaces.

✅ Moisture-resistant options – Suitable for kitchens/bathrooms.

❌ Heavier than longitudinal plywood (due to denser lamination).

❌ More expensive than standard plywood (but cheaper than high-end hardwoods).

❌ Not as strong in a single direction as longitudinal plywood (not ideal for beams).

Bamboo Strips Preparation – Split, flattened, and dried.

Layering – Strips stacked in alternating grain directions.

Pressing & Gluing – High-pressure bonding with adhesives (UF, PF, or eco-friendly resins).

Finishing – Sanding, cutting, and sometimes veneering.

Cross-ply bamboo plywood is an engineered bamboo product where layers of bamboo strips (veneers) are stacked with their grain directions perpendicular to each other (typically at 90° angles) and bonded under high pressure. This cross-lamination mimics traditional plywood construction, providing balanced strength and stability in multiple directions.

Cross-Laminated Structure

Alternating layers (usually 3, 5, or more) are arranged with grains perpendicular to each other.

Reduces expansion/contraction and warping, improving dimensional stability.

Balanced Strength

Unlike longitudinal plywood (which is strongest along the grain), cross-ply has uniform strength in both length and width.

High Durability & Moisture Resistance

Often treated with adhesives (such as phenolic resin) for water resistance, making it suitable for humid environments.

Eco-Friendly & Sustainable

Made from fast-growing bamboo, a renewable alternative to hardwood plywood.

Smooth Surface & Aesthetic Appeal

Can be sanded to a fine finish, suitable for visible surfaces in furniture and interiors.

✔ Furniture (tabletops, cabinets, shelves) – Stable and warp-resistant.

✔ Flooring & Wall Paneling – Handles heavy loads without bending.

✔ Countertops & Worktops – Resists moisture and wear.

✔ Doors & Partitions – Less prone to warping than solid wood.

✔ Structural Panels (in some cases) – Used where multi-directional strength is needed.

| Feature | Cross-Ply Bamboo Plywood | Longitudinal Bamboo Plywood |

|---|---|---|

| Grain Direction | Layers perpendicular (90°) | All layers parallel |

| Strength | Balanced in all directions | Stronger along the grain |

| Stability | More dimensionally stable | Can warp if unsupported |

| Best For | Furniture, countertops, general plywood uses | Beams, flooring, long spans |

| Moisture Resistance | Often higher (due to resins) | Depends on adhesive used |

✅ Multi-directional strength – No weak direction.

✅ Less prone to warping – Ideal for large panels.

✅ Smooth finish – Better for visible surfaces.

✅ Moisture-resistant options – Suitable for kitchens/bathrooms.

❌ Heavier than longitudinal plywood (due to denser lamination).

❌ More expensive than standard plywood (but cheaper than high-end hardwoods).

❌ Not as strong in a single direction as longitudinal plywood (not ideal for beams).

Bamboo Strips Preparation – Split, flattened, and dried.

Layering – Strips stacked in alternating grain directions.

Pressing & Gluing – High-pressure bonding with adhesives (UF, PF, or eco-friendly resins).

Finishing – Sanding, cutting, and sometimes veneering.